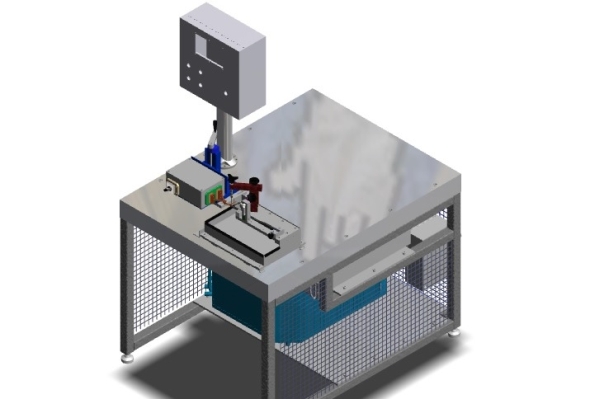

IBU105 (Induction Brazing Unit – 1 x TTH5t 5kW)

Lötanlage

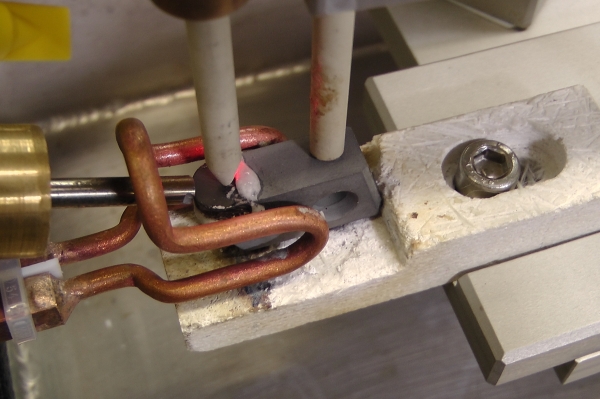

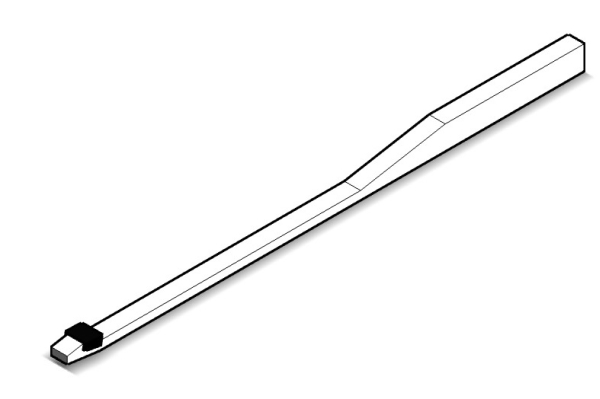

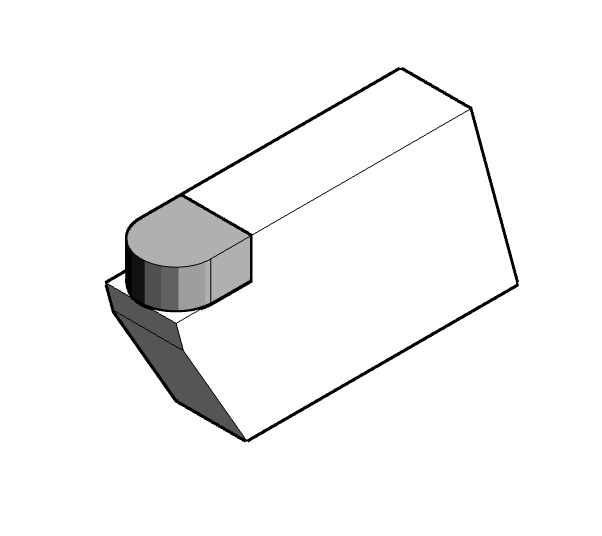

This workplace has been constructed for the inductive brazing of carbide metals as well as PCD-, PCBN-, and CBN tools.

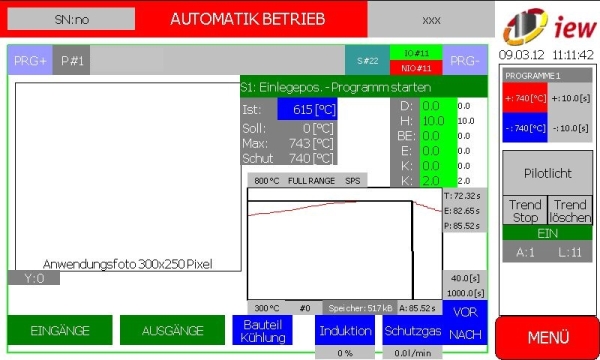

Thereby, the operator inserts the single components into the brazing device and moves them into a closed, respectively open inductor. The herein described workplace was naturally equipped with a temperature control (infrared-pyrometer) to prevent possible thermal damage (graphitization) of the diamond. Of course, this brazing device can also be equipped with a protection gas unit.

For this special customer order we also integrated a shower to simultaneously harden the workpiece. In combination with the infrared pyrometer, the PLC initializes a hardening shower after the brazing filler metal reaches the solidus temperature. However, this hardening process cannot be compared to regular hardening processes (Hardening normally at approx. 1000 °C / Brazing in this case 700 °C) but nontheless leads to an increased hardness of the workpiece.