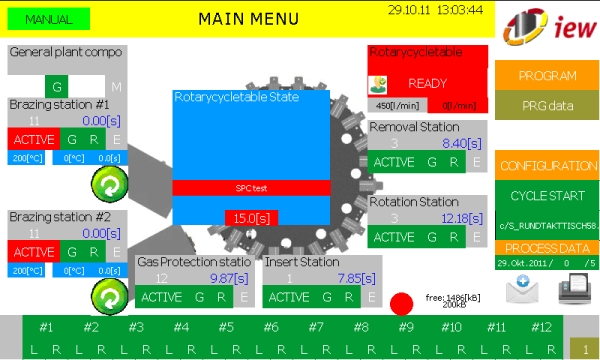

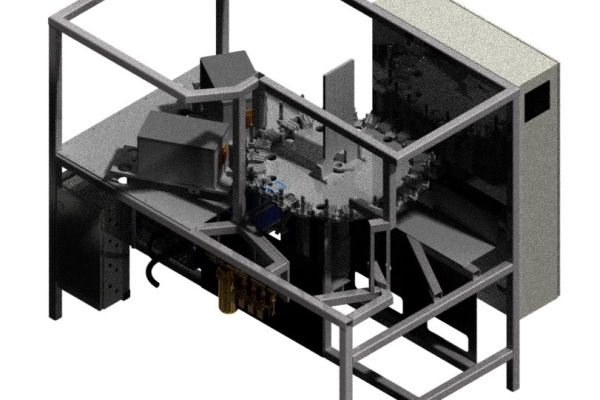

IRT210 (Induction Rotary Table – 2 x TTH10 10kW)

Lötanlage

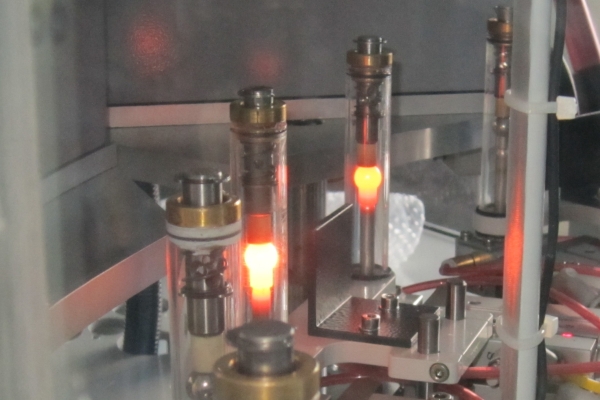

This induction round table was especially developed for the brazing of ball-type nipples onto stainless steel tubes with protective gas.

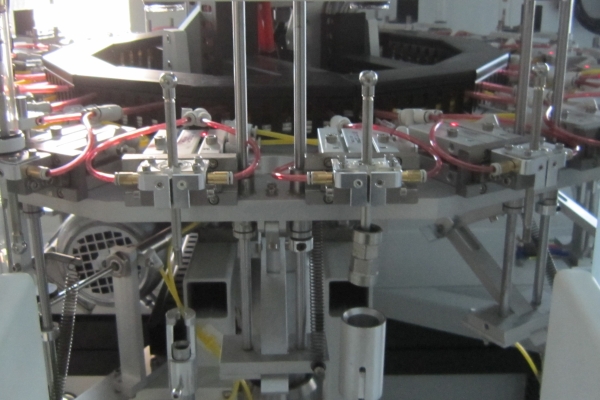

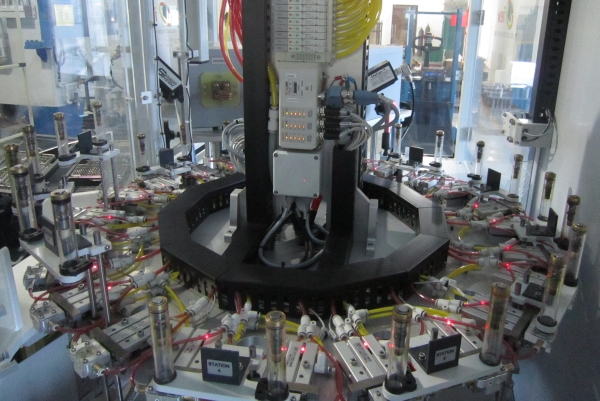

The operational procedure can be summarized as follows: A staff member inserts a new assembly group with an already mounted ball-type nipple. The ball-type nipple is brazed onto the steel tube during the first cycle, automatically rotated by 180° and then completed, after the staff member mounted the second ball-type nipple with a copper brazing preform. There are always two steel tubes infront of the operator, one for the first and one for the second brazing joint. The induction round table consists of 12 double stations.

Furthermore, the brazing assembly is equipped with a system that automatically discharges steel tubes that do not meet the prior defined brazing parameters. This prevents that n.i.o. parts are further processed. This induction round table can realise more than 2.5 million brazing joints per year.